products

Innovation

ABOUT US

Breakthrough

Nanya

INTRODUCTION

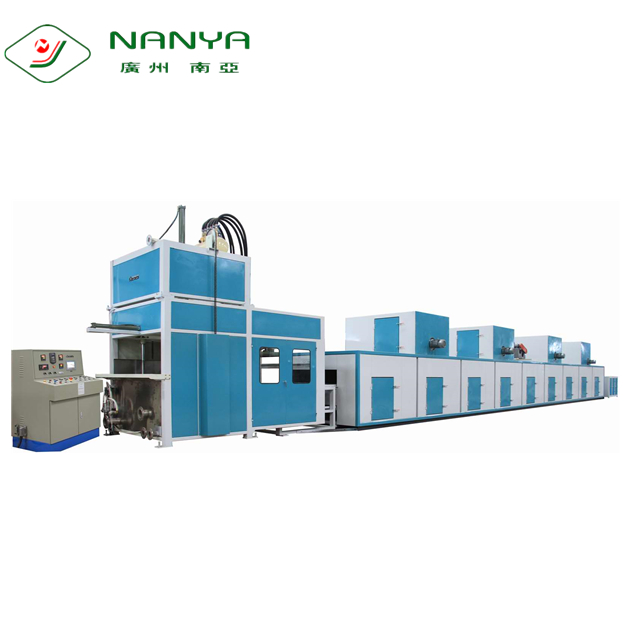

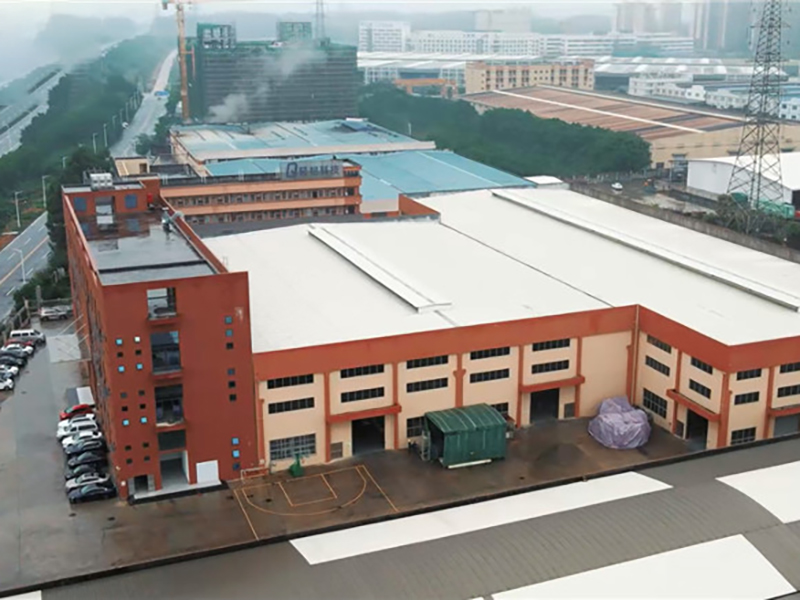

Nanya company establish in 1994,we develop and manufacture pulp molded machine with over 20 years’ experience.It’s the first and the biggest enterprise that make pulp molding equipment in China. We are specialized in the production of dry press & wet press pulp molded machines(pulp molding tableware machine,pulp molded finery packaging machines,egg tray/fruit tray/cup holder tray machines,pulp molded industry packaging machine).

-

-FOUNDED IN 1994

-

-29 YEARS EXPERIENCE

-

-MORE THAN 50 PRODUCTS

-

-MORE THAN 20 BILLION

NEWS

Service First

-

Guangzhou Nanya Pulp Molding Auxiliary Equipment & Spare Parts Shipped to Brazil, Improving South American Production Support

Recently, a batch of pulp molding auxiliary equipment and core spare parts from Guangzhou Nanya Pulp Molding Equipment Co., Ltd. was loaded into containers and shipped to Brazil! This shipment includes key auxiliary equipment such as vertical pulpers and pressure screens...

-

In the Smart Factory Era, Guangzhou Nanya Leads the Intelligent Upgrade of Pulp Molding Equipment

In October 2025, industry analysis reports show that global demand for pulp molding packaging continues to rise. Driven by the threefold impetus of deepened "plastic ban" policies worldwide, tightened "dual-carbon" regulations, and the full penetration of sustainable dev...