products

Innovation

ABOUT US

Breakthrough

Nanya

INTRODUCTION

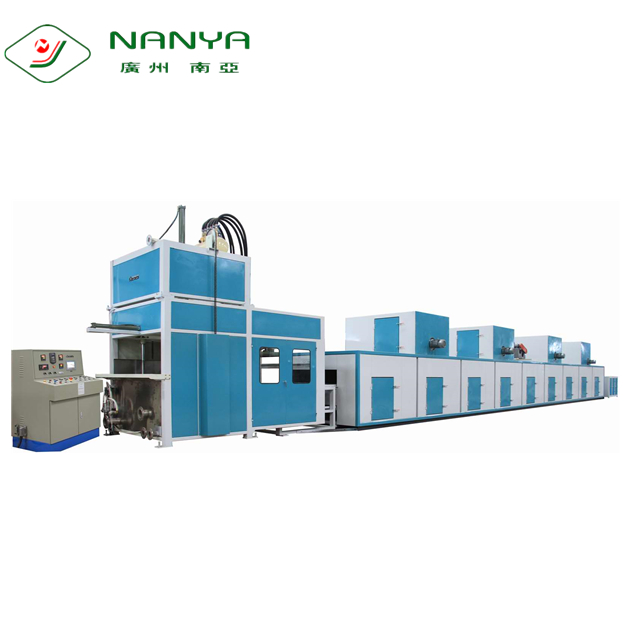

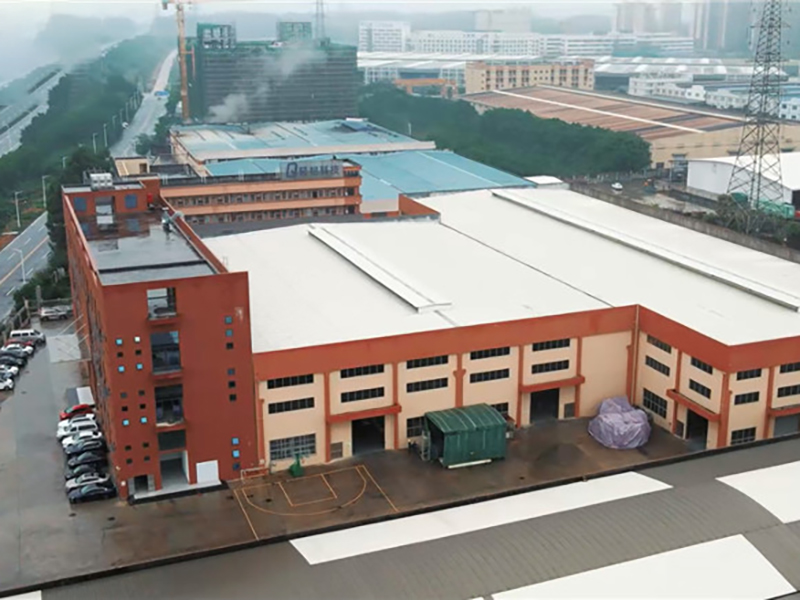

Nanya company establish in 1994,we develop and manufacture pulp molded machine with over 20 years’ experience.It’s the first and the biggest enterprise that make pulp molding equipment in China. We are specialized in the production of dry press & wet press pulp molded machines(pulp molding tableware machine,pulp molded finery packaging machines,egg tray/fruit tray/cup holder tray machines,pulp molded industry packaging machine).

-

-FOUNDED IN 1994

-

-29 YEARS EXPERIENCE

-

-MORE THAN 50 PRODUCTS

-

-MORE THAN 20 BILLION

NEWS

Service First

-

Exhibition Review! | 136th Canton Fair, Nanya Promotes Green Packaging Trend with Pulp Molding Equipment

From October 15th to 19th, Nanya participated in the 136th Canton Fair, where she showcased the latest pulp molding solutions and technologies, including pulp molding robot tableware machines, high-end pulp molding work bag machines, pulp molding coffee cup holders, pulp molding egg trays and egg...

-

Foshan IPFM Exhibition in 2024. Welcome to visit our Booth for further communication

International Plant Fiber Molding Industry Exhibition Paper Plastic Packaging Materials & Products Application Innovation Exhibition! The exhibition is hold on today, Welcome everyone come to our booth to see the samples and discuss further. Guangzhou Nanya Pulp Molding Equipment Co., Ltd F...